In recent years, DTF printing—short for Direct-to-Film printing—has become one of the most popular methods for custom apparel decoration. It’s fast, cost-effective, and works on a wide range of fabrics. But what exactly is DTF printing, how does it work, and what makes it so special? Let’s break it down.

What is DTF Printing?

DTF printing is a digital printing process that transfers designs onto a special PET film using DTF ink. The printed film is then coated with a hot-melt adhesive powder, cured, and finally heat-pressed onto the fabric.

In simple terms, it’s a two-step process:

- Print the design on film using a DTF printer.

- Transfer it to fabric using a heat press.

The result is a vibrant, durable, and flexible print that feels smooth and lasts for many washes.

How Does DTF Printing Work?

The DTF printing process involves several steps:

1. Design Creation

Designs are created digitally using software such as Adobe Photoshop, Illustrator, or CorelDRAW. Once complete, the image is mirrored before printing.

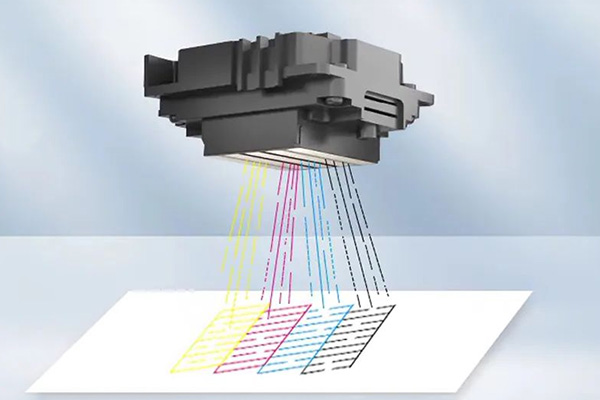

2. Printing on PET Film

A DTF printer prints the image in full color using special DTF inks (CMYK + White). The white ink layer ensures the design looks vivid on any fabric color.

3. Applying Adhesive Powder

After printing, hot-melt adhesive powder is applied evenly to the wet ink. This powder acts as a bonding agent between the design and the fabric.

4. Curing

The film is heated (usually 100–120°C for a few minutes) to melt and activate the adhesive powder.

5. Heat Press Transfer

The prepared film is placed on the fabric, then heat-pressed at around 160°C (320°F) for 15–20 seconds. After cooling, the film is peeled off—leaving the design permanently bonded to the material.

What Fabrics Can You Use for DTF Printing?

One of the biggest strengths of DTF technology is its material versatility. You can apply DTF transfers to:

- Cotton

- Polyester

- Blends

- Nylon

- Leather

- Denim

- Canvas

Whether you’re printing on light or dark fabrics, DTF provides excellent color vibrancy and stretch resistance.

Advantages of DTF Printing

DTF printing has gained huge popularity for good reason. Here are some of its biggest benefits:

Works on Almost Any Fabric

Unlike DTG (Direct-to-Garment) printing, which only works on cotton, DTF can print on cotton, polyester, blends, nylon, leather, and more.

Vivid Colors and Fine Details

DTF produces bright, high-resolution prints that capture small text and detailed artwork.

Durability

The adhesive powder creates a strong bond, making prints resistant to cracking, fading, and peeling—even after multiple washes.

Cost-Effective for Small Batches

Since there’s no need for pre-treatment or screens, DTF is ideal for small orders, custom designs, and on-demand printing.

Easy to Apply

Once printed, DTF transfers can be stored and pressed later—great for bulk preparation and time efficiency.

DTF vs DTG vs Screen vs Sublimation Printing

To understand where DTF stands, let’s compare it with other popular printing methods — DTG, Screen Printing, and Sublimation.

| Feature | DTF Printing | DTG Printing | Screen Printing | Sublimation Printing |

|---|---|---|---|---|

| Fabric Compatibility | Cotton, Polyester, Blends | Cotton only | Cotton, Polyester | Polyester only |

| Pre-treatment Needed | No | Yes | No | No |

| Durability | ★★★★★ | ★★★★☆ | ★★★★★ | ★★★★★ |

| Color Vibrancy | ★★★★★ | ★★★★☆ | ★★★★☆ | ★★★★★ |

| Texture Feel | Smooth & flexible | Soft & natural | Slightly raised | Part of fabric |

| Setup Cost | Low | Medium | High | Medium |

| Best For | All-around versatility | Cotton-based designs | Bulk orders | Polyester & promotional items |

Which Printing Method Should You Choose?

Your choice depends on your fabric type, order volume, and desired finish:

- Choose DTF if you want one technology for all fabric types.

- Choose DTG for soft, high-resolution prints on cotton shirts.

- Choose screen printing for large, simple, and durable designs.

- Choose sublimation printing for vibrant prints on polyester sportswear or promotional products.

If you’re just starting a print business or want flexibility across different products, DTF printing offers the best balance between quality, cost, and material compatibility.

Common Applications of DTF Printing

- Custom T-shirts and hoodies

- Sportswear and uniforms

- Tote bags and caps

- Workwear and promotional apparel

- Pillowcases and fabric accessories

What Equipment Do You Need for DTF Printing?

To start DTF printing, you’ll need:

- DTF printer (capable of printing CMYK+White)

- PET film (transfer film)

- DTF inks

- Hot-melt adhesive powder

- Curing oven or heat press

- Design software (e.g., Photoshop, CorelDRAW)

Many suppliers now offer DTF printer bundles that include all the necessary components for beginners.

Final Thoughts

DTF printing is revolutionizing the custom apparel industry with its versatility, affordability, and outstanding print quality. Whether you’re starting a small t-shirt brand or expanding your printing business, investing in DTF technology can help you deliver professional, full-color results on any fabric — fast.