In recent years, Direct-to-Film (DTF) printing has become one of the most talked-about printing methods in the apparel and custom merchandise industry. Compared to traditional methods like screen printing, sublimation, or DTG (Direct-to-Garment), DTF printers offer unique benefits but also come with certain limitations. If you are considering investing in a DTF printer for your business, it’s important to weigh the pros and cons carefully.

What is DTF Printing?

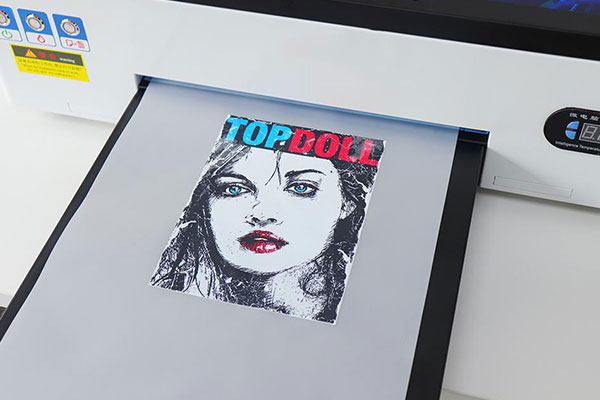

DTF printing is a process where designs are printed directly onto a special film using water-based pigment inks. The film is then coated with a hot-melt adhesive powder, cured, and transferred onto fabric or other surfaces using a heat press. This method allows for high-quality, full-color prints on a wide range of materials.

Advantages of DTF Printers

1. Versatility in Printing

Unlike sublimation, which is limited to polyester fabrics, or screen printing, which requires specific setups, DTF printers can print on cotton, polyester, blends, leather, and more. This makes them suitable for various industries, from fashion to promotional merchandise.

2. Vivid and Durable Prints

DTF technology produces bright colors and sharp details, even on dark fabrics. The prints are also highly durable, resistant to cracking and fading after multiple washes.

3. No Need for Pre-Treatment

With DTG printing, garments often require pre-treatment before printing. DTF printing eliminates this step, saving time and reducing labor costs.

4. Cost-Effective for Small and Large Orders

DTF is efficient for short runs and bulk orders alike. Small businesses benefit from the low setup costs, while larger operations can produce high volumes without sacrificing quality.

5. Stock Transfers for On-Demand Use

One unique advantage is that you can print and store DTF transfers ahead of time. These can be applied later, allowing for faster turnaround when orders come in.

Disadvantages of DTF Printers

1. Initial Investment Cost

High-quality DTF printers and curing equipment can be expensive. For small businesses just starting out, the upfront cost may be a challenge.

2. Maintenance Requirements

DTF printers require regular cleaning and maintenance to avoid ink clogging and ensure consistent print quality. Neglecting this can lead to costly repairs.

3. Learning Curve

Although easier than screen printing, DTF printing still requires technical knowledge about inks, films, powders, and heat settings. Beginners may face a learning curve before mastering the process.

4. Environmental Concerns

The hot-melt adhesive powder and films are not always eco-friendly, raising concerns for businesses aiming for sustainable production. Proper disposal of waste materials is necessary.

Is DTF Printing Right for Your Business?

DTF printing offers a strong balance of quality, versatility, and efficiency, making it a popular choice for custom apparel businesses, print shops, and entrepreneurs. However, the higher startup costs and maintenance requirements mean it’s best suited for those serious about long-term production.

If your business values flexibility, vibrant prints, and the ability to work with multiple fabric types, investing in a DTF printer can be a smart move. On the other hand, if you are looking only for low-cost, eco-friendly solutions, you may want to explore alternatives such as sublimation or screen printing.

Final Thoughts

Understanding the advantages and disadvantages of DTF printers helps you make an informed decision before investing. As with any printing technology, success depends on matching the right tool with your business goals, target market, and production needs.